FRCcrete®

This is concrete containing fibres which increases its structural integrity. Depending upon application, various fibres like Steel, Glass & Synthetic Fibres are used.

Application

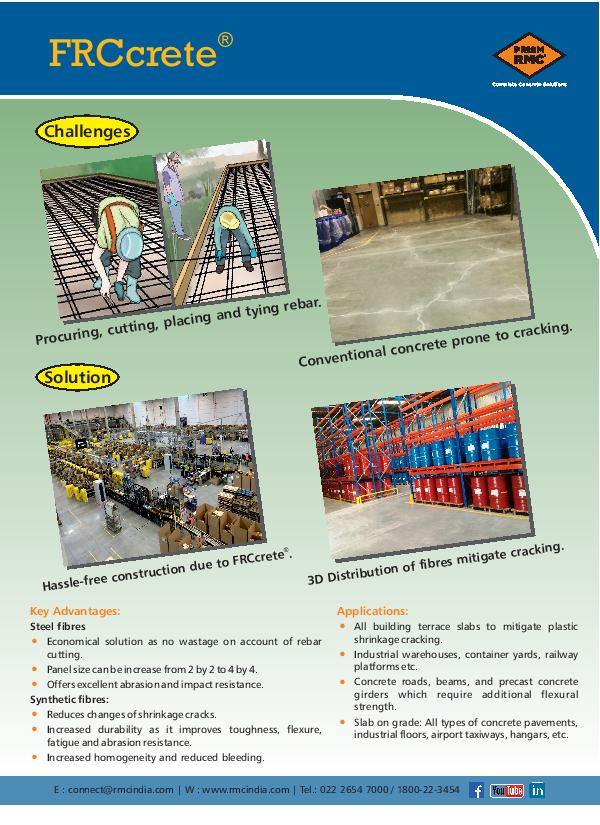

1. All building terrace slabs to mitigate plastic shrinkage cracking.

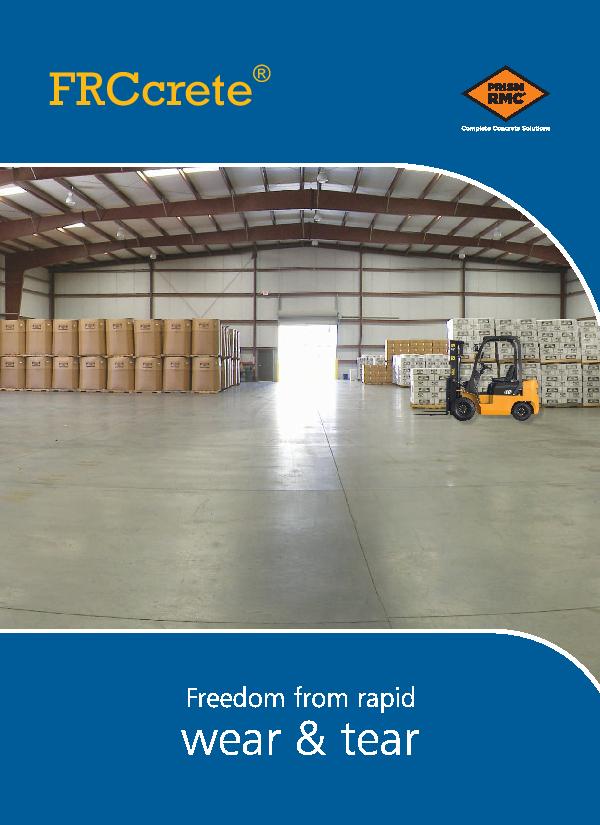

2. Industrial warehouses, container yards, railway platforms etc.

3. Concrete roads, beams, and precast concrete girders which require additional flexural strength.

4. Slab on grade: All types of concrete pavements, industrial floors, airport taxiways, hangars, etc.

1. All building terrace slabs to mitigate plastic shrinkage cracking.

2. Industrial warehouses, container yards, railway platforms etc.

3. Concrete roads, beams, and precast concrete girders which require additional flexural strength.

4. Slab on grade: All types of concrete pavements, industrial floors, airport taxiways, hangars, etc.

Advantages

Steel fibres

1. Economical solution as no wastage on account of rebar cutting.

2. Panel size can be increase from 2 by 2 to 4 by 4.

3. Offers excellent abrasion and impact resistance.

Synthetic fibres:

1. Reduces changes of shrinkage cracks.

2. Increased durability as it improves toughness, flexure, fatigue and abrasion resistance.

3. Increased homogeneity and reduced bleeding.

Steel fibres

1. Economical solution as no wastage on account of rebar cutting.

2. Panel size can be increase from 2 by 2 to 4 by 4.

3. Offers excellent abrasion and impact resistance.

Synthetic fibres:

1. Reduces changes of shrinkage cracks.

2. Increased durability as it improves toughness, flexure, fatigue and abrasion resistance.

3. Increased homogeneity and reduced bleeding.

Scan the barcode to get the brochure on your phone.

See Product Video

View All Products

See Product Video

View All Products